Thermostatic regulators connection system (IoT)

One of the most important hydronic solutions manufacturers, assigned us the project of their new “Thermostatic regulation system” whose function is to achieve and maintain comfort conditions within a living space (thermal well-being), controlling thermal emission in order to release heat only when needed (energy saving).

Connectivity and the ability to manage the entire living comfort through a specific App is a fundamental point of this system.

To achieve the required objectives, it was necessary to develop an interconnected regulation system, where the various devices communicate each other through RF868-based wireless communications.

The system is composed by following devices:

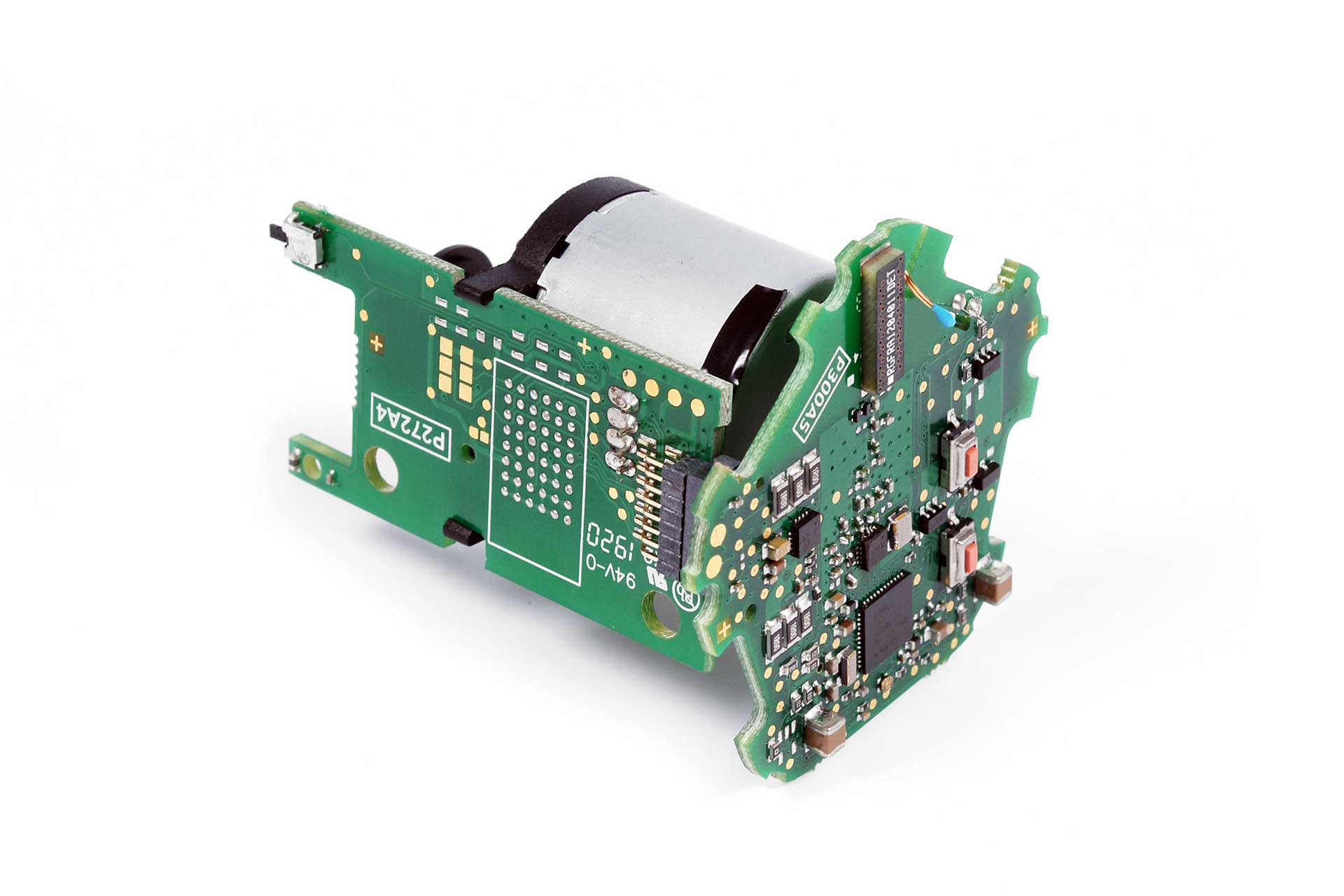

Radiator Valve

The radiator valve is the heart of the system: a battery-powered wireless electronic device (2×1.5V) mounted on each individual radiator in the apartment. The value of the room temperature detected by the internal sensor (or by an optional room temperature sensor) is compared with the setpoint and, using a PID regulator, the stepper motor integrated into the valve is activated to increase or decrease the heat flow.

The set point value, set remotely through the App (then forwarded using RF), can also be forced locally using the buttons on the valve.

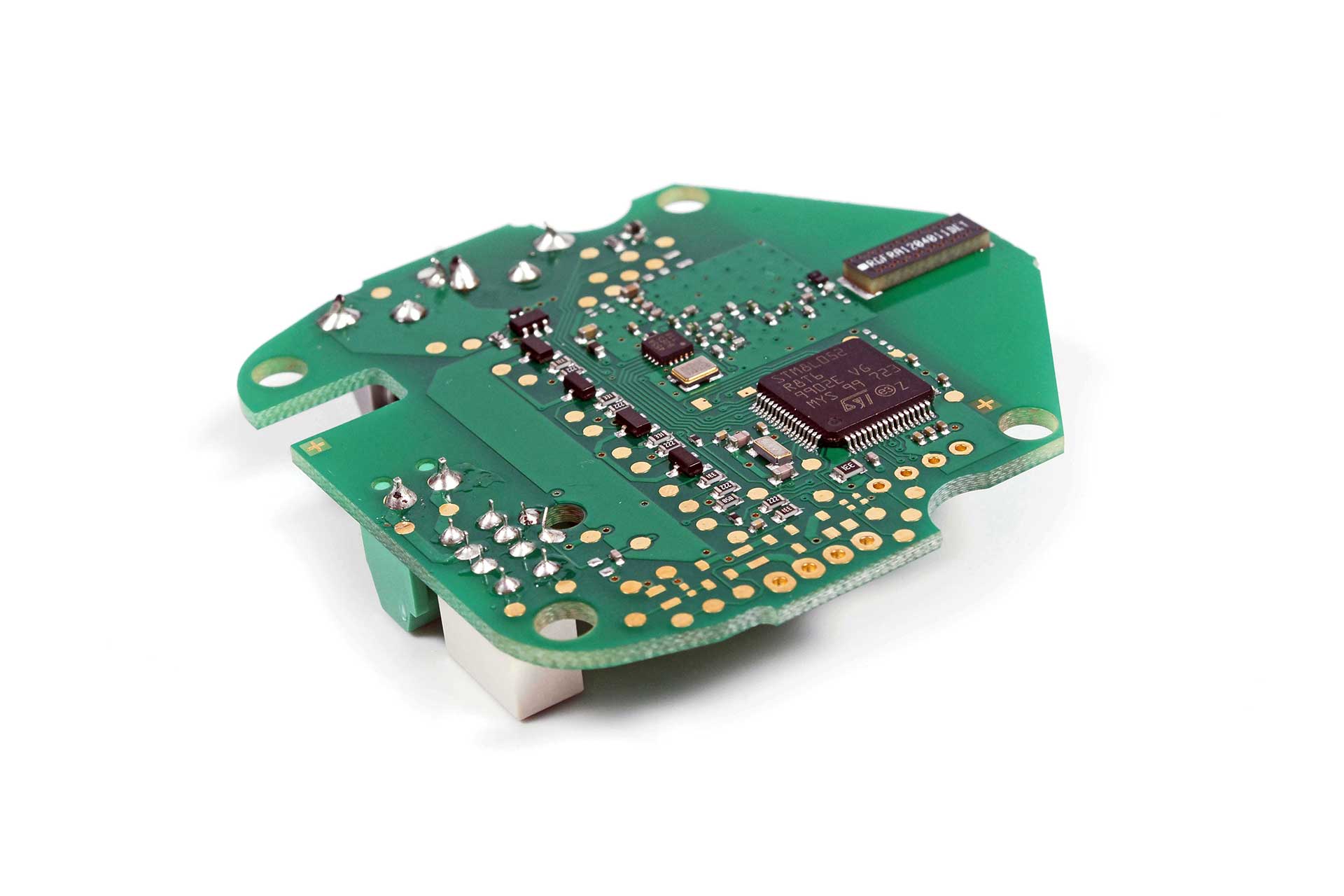

Room temperature sensor

The room temperature sensor is a battery-powered (2×1.5V) wireless electronic device, used to detect the ambient temperature.

When room temperature detected from the thermostatic valve is too affected from its position, performance can be significantly improved with its installation.

The readed temperature is sent to the gateway, which makes it available to the valves installed in affected area.

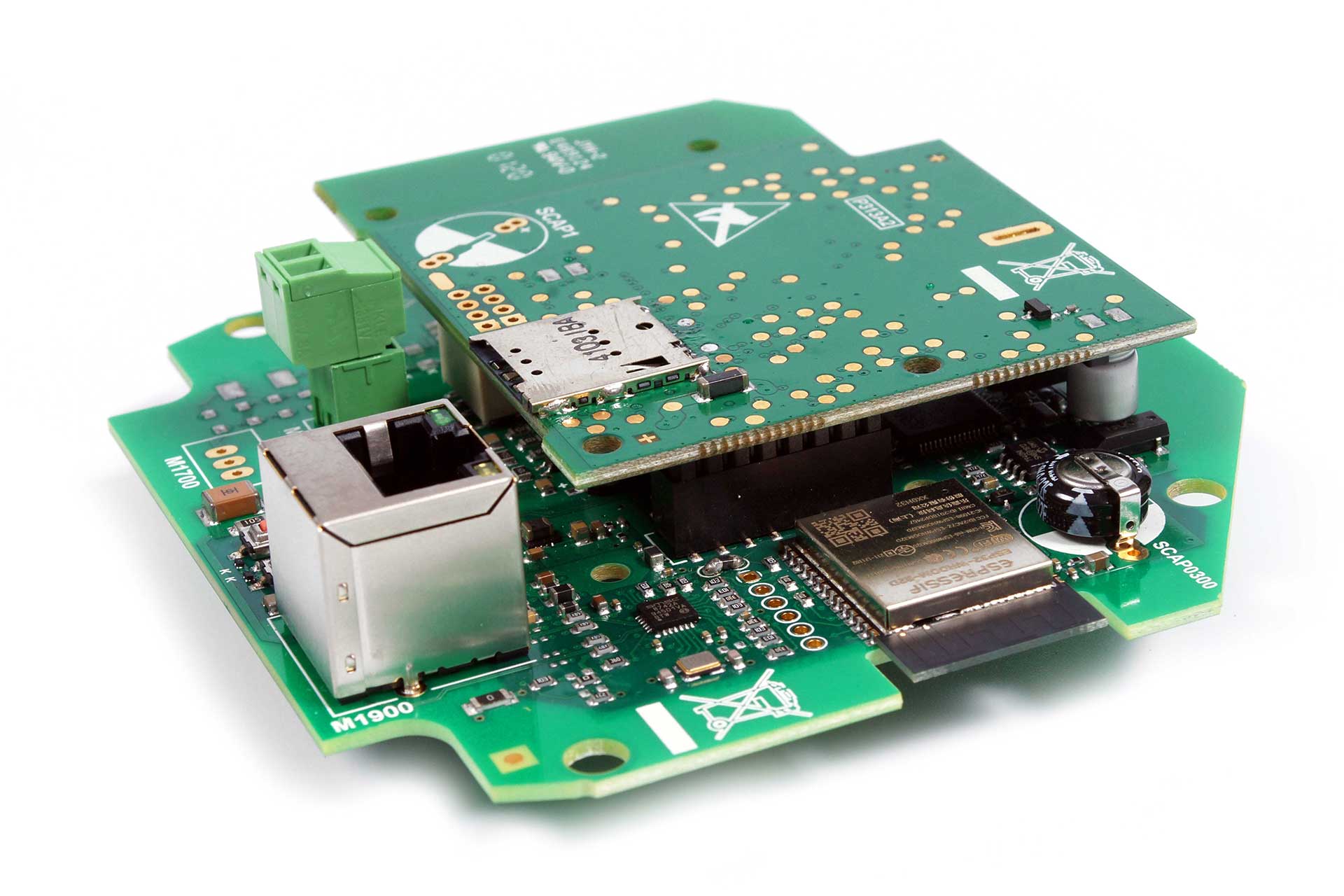

Gateway

The gateway is the collector of all system information, it guarantees integration by interacting with the user and controlling valves and sensors via 868 MHz RF.

Communication with the outside world, can take place through different communication channels:

- Wi-fi

- GSM

- Ethernet

- Bluetooth

- Modbus

It allows a weekly program for 64 zones and up to 8 daily time bands, giving however the possibility of rapid/timed forcing (manual, ECO, holidays, Jolly ..)

The request for heat to the boiler can be managed by means of ON-OFF contacts (both on gateway and sensors) or via Opentherm communication: in the last case a PID modulation could also be done.

The entire system has been internally designed and will be in mass production by the end of 2020.